This month we spoke to Joe Melendez, the operations director at Ocotillo Village Health Club about aquatics operations.

What are the biggest challenges to aquatics operations?

Joe Melendez: The challenges for the outdoor pools vary with the weather, including maintaining the temperature in the hotter season and keeping debris out. One example would be trying to cool a pool to 84 degrees in 110-degree heat on a day with 30% humidity and no breeze — this can be difficult if you’re relying on a cooling tower. A second example would be when we have our haboobs — dust storms — which bring in very fine dust that quickly coats the pool floors and covers the surface with debris.

How are you overcoming those challenges?

JM: The way we deal with each challenge is by keeping a consistent schedule and being as prepared as possible. Keeping a mobile vacuum with a separate filter helps us keep the downtime to a minimum. During hotter months we keep a sort of water jet or aerator to supplement what is being cooled in our chiller tower. I find when there is no breeze you can still cool the water by forcing it in through smaller orifices and causing a mist, rather than simply buying a commercial aerator that throws your pool water over the length of your pool.

The indoor pool presents its own challenges. Unlike a hotel or private residence where few people enter the whirlpools or pools, our pool usage is consistent and they are being used as part of a health routine. This means those who use the facility and the amenities we provide expect the bodies of water to match the rest of the club.

The challenge with whirlpools is keeping the chemical levels and the whirlpools themselves within the acceptable range. These can be affected by somebody who decides they would rather rinse off in the whirlpool after a workout than shower beforehand.

How do you maximize usage and prevent downtime?

JM: It begins with the testing of the water daily, knowing your water life per pool, and if possible, investing in a chemical controller that sends you updates when the water chemical is out of the acceptable range. I have recently had the BECSys5 controller installed on our whirlpool with the higher usage and most pH fluctuations. It has helped me troubleshoot whether it is an issue caused by usage or our maintenance. Keeping track of water chemistry and filter pressures is not just for the protection of the members and to keep inspectors off your back. Daily logs are a very helpful tool when trying to troubleshoot a system.

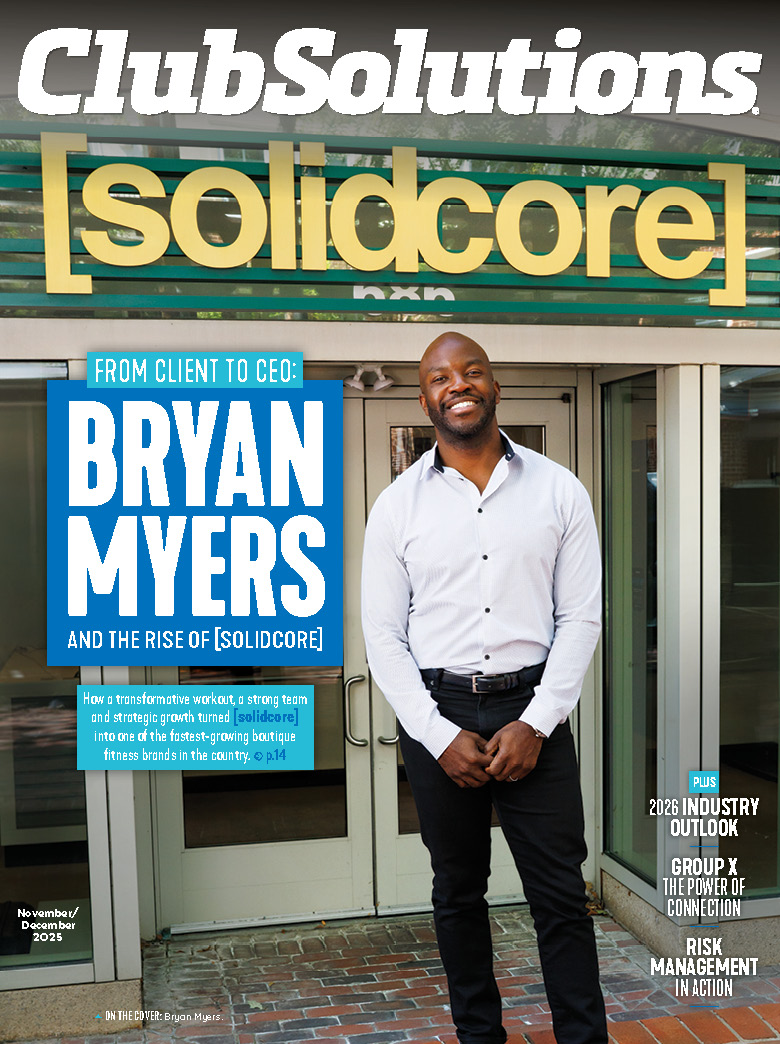

![From Client to CEO: Bryan Myers and the Rise of [solidcore]](https://d296qbqev3kq48.cloudfront.net/wp-content/uploads/2025/11/06151333/CS-NovDec25-CoverStory-3-350x250.jpg)